Amorphous Nanocrystalline Core Winding Machine

Jan 22, 2025

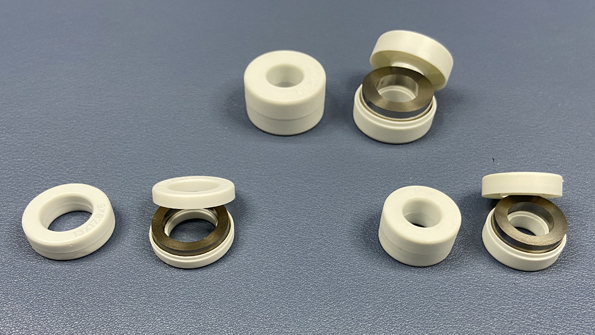

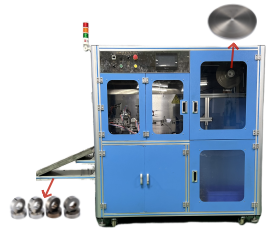

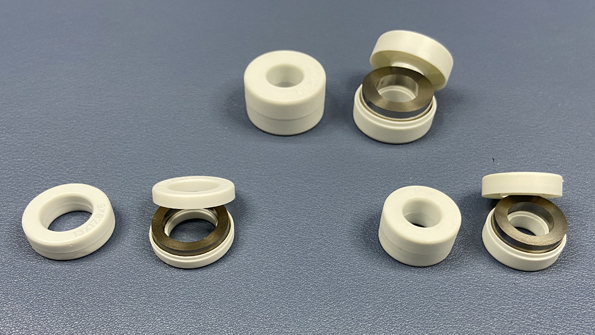

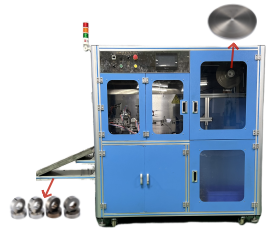

The Amorphous Nanocrystalline Core Winding Machine is an automated device specifically used to wind amorphous alloy strips or nanocrystalline alloy strips into magnetic cores of various specifications. This equipment is widely used in industries such as electronics and power, especially in high-frequency transformers, filters, sensors, and other fields.

Advantages of Amorphous Nanocrystalline Cores

Before introducing the winding machine, let’s first understand the advantages of amorphous nanocrystalline cores:

High Permeability: Amorphous nanocrystalline cores have a higher magnetic permeability than traditional silicon steel sheets, which helps reduce the size and weight of the core.

Low Losses: These cores have lower iron losses and eddy current losses, improving the efficiency of devices.

Excellent High-Frequency Performance: They exhibit lower core losses and higher permeability at high frequencies, making them suitable for high-frequency applications.

Excellent Soft Magnetic Properties: With low coercivity, they are easy to magnetize and demagnetize.

Structure and Function of the Amorphous Nanocrystalline Core Winding Machine

The Amorphous Nanocrystalline Core Winding Machine mainly consists of the following components:

Feeding Device: Feeds the amorphous or nanocrystalline alloy strip into the winding machine.

Tension Control Device: Controls the tension of the strip to ensure uniform winding.

Winding Mechanism: Drives the core mold to rotate, winding the strip around the core mold.

Cutting Device: Cuts the strip after it reaches the specified number of turns, forming the magnetic core.

Winding Process

Feeding: The amorphous or nanocrystalline alloy strip is fed from the material reel and its tension is controlled by the tension control device.

Winding: The strip is wound around the rotating core mold to form the magnetic core. During the winding process, the winding speed and tension can be adjusted to control the thickness and uniformity of the core.

Cutting: When the required number of turns is reached, the cutting device will cut the strip, forming a complete magnetic core.

Features of the Amorphous Nanocrystalline Core Winding Machine

High Precision: The machine can precisely control the size and number of turns of the magnetic core, ensuring product quality.

High Efficiency: The high degree of automation leads to high production efficiency.

Flexibility: It can be quickly adjusted to accommodate different core specifications.

Applications of the Amorphous Nanocrystalline Core Winding Machine

The Amorphous Nanocrystalline Core Winding Machine is widely used in the following fields:

Power Electronics: Manufacturing high-frequency transformers, filters, common-mode chokes, etc.

Communication Equipment: Producing magnetic beads, magnetic rings, etc.

Automotive Electronics: Manufacturing magnetic components for automotive electronic controllers.

New Energy: Producing magnetic components for solar inverters, charging stations, and other equipment.

The Amorphous Nanocrystalline Core Winding Machine plays an important role in the modern electronics industry. With the trend toward miniaturization, higher frequencies, and higher efficiency in electronic devices, the demand for amorphous nanocrystalline cores will continue to grow. As a result, the technological level of the winding machine will also continue to improve.

Advantages of Amorphous Nanocrystalline Cores

Before introducing the winding machine, let’s first understand the advantages of amorphous nanocrystalline cores:

High Permeability: Amorphous nanocrystalline cores have a higher magnetic permeability than traditional silicon steel sheets, which helps reduce the size and weight of the core.

Low Losses: These cores have lower iron losses and eddy current losses, improving the efficiency of devices.

Excellent High-Frequency Performance: They exhibit lower core losses and higher permeability at high frequencies, making them suitable for high-frequency applications.

Excellent Soft Magnetic Properties: With low coercivity, they are easy to magnetize and demagnetize.

Structure and Function of the Amorphous Nanocrystalline Core Winding Machine

The Amorphous Nanocrystalline Core Winding Machine mainly consists of the following components:

Feeding Device: Feeds the amorphous or nanocrystalline alloy strip into the winding machine.

Tension Control Device: Controls the tension of the strip to ensure uniform winding.

Winding Mechanism: Drives the core mold to rotate, winding the strip around the core mold.

Cutting Device: Cuts the strip after it reaches the specified number of turns, forming the magnetic core.

Winding Process

Feeding: The amorphous or nanocrystalline alloy strip is fed from the material reel and its tension is controlled by the tension control device.

Winding: The strip is wound around the rotating core mold to form the magnetic core. During the winding process, the winding speed and tension can be adjusted to control the thickness and uniformity of the core.

Cutting: When the required number of turns is reached, the cutting device will cut the strip, forming a complete magnetic core.

Features of the Amorphous Nanocrystalline Core Winding Machine

High Precision: The machine can precisely control the size and number of turns of the magnetic core, ensuring product quality.

High Efficiency: The high degree of automation leads to high production efficiency.

Flexibility: It can be quickly adjusted to accommodate different core specifications.

Applications of the Amorphous Nanocrystalline Core Winding Machine

The Amorphous Nanocrystalline Core Winding Machine is widely used in the following fields:

Power Electronics: Manufacturing high-frequency transformers, filters, common-mode chokes, etc.

Communication Equipment: Producing magnetic beads, magnetic rings, etc.

Automotive Electronics: Manufacturing magnetic components for automotive electronic controllers.

New Energy: Producing magnetic components for solar inverters, charging stations, and other equipment.

The Amorphous Nanocrystalline Core Winding Machine plays an important role in the modern electronics industry. With the trend toward miniaturization, higher frequencies, and higher efficiency in electronic devices, the demand for amorphous nanocrystalline cores will continue to grow. As a result, the technological level of the winding machine will also continue to improve.

Previous: National Holiday Notice

Next: National Holiday Notice