1-6 Inch Wire Nail Making Machine Z94 Series

Introduction

Common wire nail making machine adopts plunger type structure to ensure its high working speed, low noise and low impact characteristics.

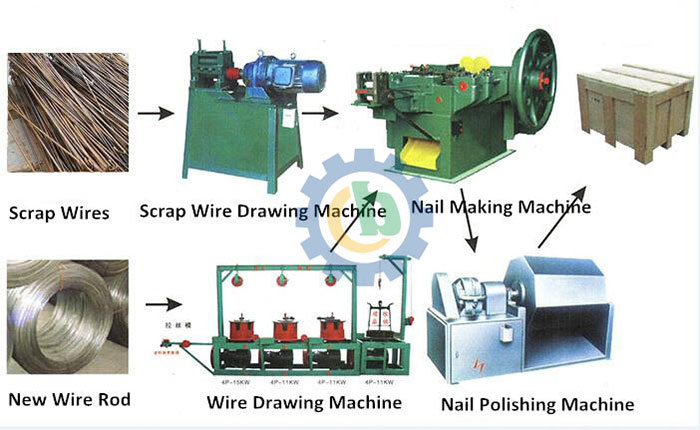

The processing flow is based on your original material:

1. Scrap Wires→ Scrap Wire Drawing Machine → Nail Forming → Nail Polishing → Finished Nails → Package

2. New Wire Rod→ Wire Drawing Machine→ Nail Making → Nail Polishing → Finished Nails → Package

01 Z-94 Series Nail Making Machine

Common wire nail making machine adopts plunger type structure to ensure its high working speed, low noise and low impact characteristics. It has wide uses, simple operation, and reliable working condition. The raw material can be waste scrap or new wire rod. The nail point and the nail head can be formed at one time with a high efficiency.

02 Combined Continuous Wire Drawing Machine

This combined continuous wire drawing machine is sturdy and durable with extremely low maintenance ratio by using the canine round seal lubrication. This machine can be used as a single one or combined together.

03 Nail Polishing Machine

This kind of machine is used for polishing the nails. Generally, one time polishing needs 3.5 hours or so. You should also put the wood chips and the paraffin together which will make the finished nails bright enough.

Accessory equipment

01 Knife Grinding Machine

02 Butt Welding Machine

03 Nail Pointing Machine

Technical Parameter

| Technical Items | Unit | Z94-6.5C | Z94-5C | Z94-4C | Z94-3C | Z94-2C | Z94-1C |

| Diameter of nail Max | mm | 6.5 | 5.5 | 4.5 | 3.4 | 2.8 | 1.6 |

| Diameter of nail Min | mm | 4.5 | 3.7 | 2.8 | 1.8 | 1.2 | 0.9 |

| Length of nail Max | mm | 200 | 150 | 100 | 75 | 50 | 25 |

| Length of nail Min | mm | 100 | 80 | 50 | 30 | 16 | 9 |

| Designed output | pcs/min | 160 | 200 | 280 | 320 | 350 | 450 |

| Motor power | kw | 11 | 5.5 | 4 | 3 | 3 | 1.5 |

| Overall size | mm | 3200×2200×2200 | 2380×1580×1660 | 2120×1540×1590 | 1800×1260×1460 | 1645×1215×1345 | 1440×1040×1270 |

| Weight | kg | 2800 | 2200 | 1900 | 1100 | 750 | 450 |

Note: 1 inch = 25.4 mm

Request a Quote