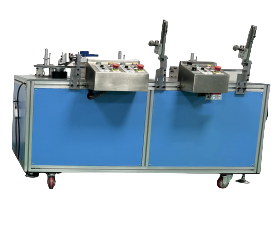

Nanocrystalline Ribbon Making Machine

This nano ribbon making machine is our hot sale machine this year, for export machine, our engineer can go abroad for installation.

Introduction

This nano ribbon making machine is our hot sale machine this year, for export machine, our engineer can go abroad for installation. Four engineers need go to installation. The nanocrystalline ribbon is high quality produced by our machine.

The alloyed metal solution is sprayed onto the water-cooled copper roller through pressure. Rapid cooling at a cooling rate of 1 million °C/second to form amorphous and nanocrystalline ribbons.

The alloyed metal solution is sprayed onto the water-cooled copper roller through pressure. Rapid cooling at a cooling rate of 1 million °C/second to form amorphous and nanocrystalline ribbons.

Technical Parameter

| Name | Parameters |

| Total equipment power: | 150KW |

| Medium frequency furnace power: | 120KW |

| Rated capacity of intermediate frequency furnace: | 100KG |

| Maximum operating temperature of intermediate frequency furnace: | 1650℃ |

| Medium frequency furnace operating temperature: | 1450℃ |

| Medium frequency furnace temperature control accuracy: | +/- 3℃ |

| Stirring method: | magnetic field |

| Medium frequency furnace/cooling plate | 50m3/h |

| Distilled water minimum water flow: Belt making machine | 60-80m3/h |

| Water pressure: Medium frequency furnace | ≥ 0.18MPa |

| Water Pressure: Belt Making Machine | ≥0.25MPa |

| Water quality: intermediate frequency furnace/Belt making machine | PH value7~8.5 |

| Inlet water temperature: Intermediate frequency furnace/ribbon making machine | ≤35℃ |

| Water temperature difference between inlet and outlet: ribbon making machine | ≤3℃ |

| Argon pressure | 25KPa |

| Copper roller diameter | 630mm |

| Copper roller width | 400mm |

| Copper roller thickness | 40mm |

| Servo mechanism spray belt pressing accuracy | 1um |

| Roller runout | ﹤1μm |

Consumption indicators

| Item | Point of use | Dosage | Remark | |

| Water | softened water | Medium frequency furnace | Strip consumption per ton is 0.01 tons | |

| distilled water | Belt making main machine | Strip consumption per ton is 0.01 tons | ||

| Air | compressed air | stripper | Each ton of strip consumes 80m3 | |

| Crucible plug rod cylinder | Each ton of strip consumes 10m3 | |||

| Argon | Crucible | Each ton of strip consumes 6.5 kilograms | ||

| Grease | Medium frequency furnace | Annual consumption 5kg | ||

| Main machine | ||||

| Rocker arm lifting mechanism | ||||

Request a Quote